Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

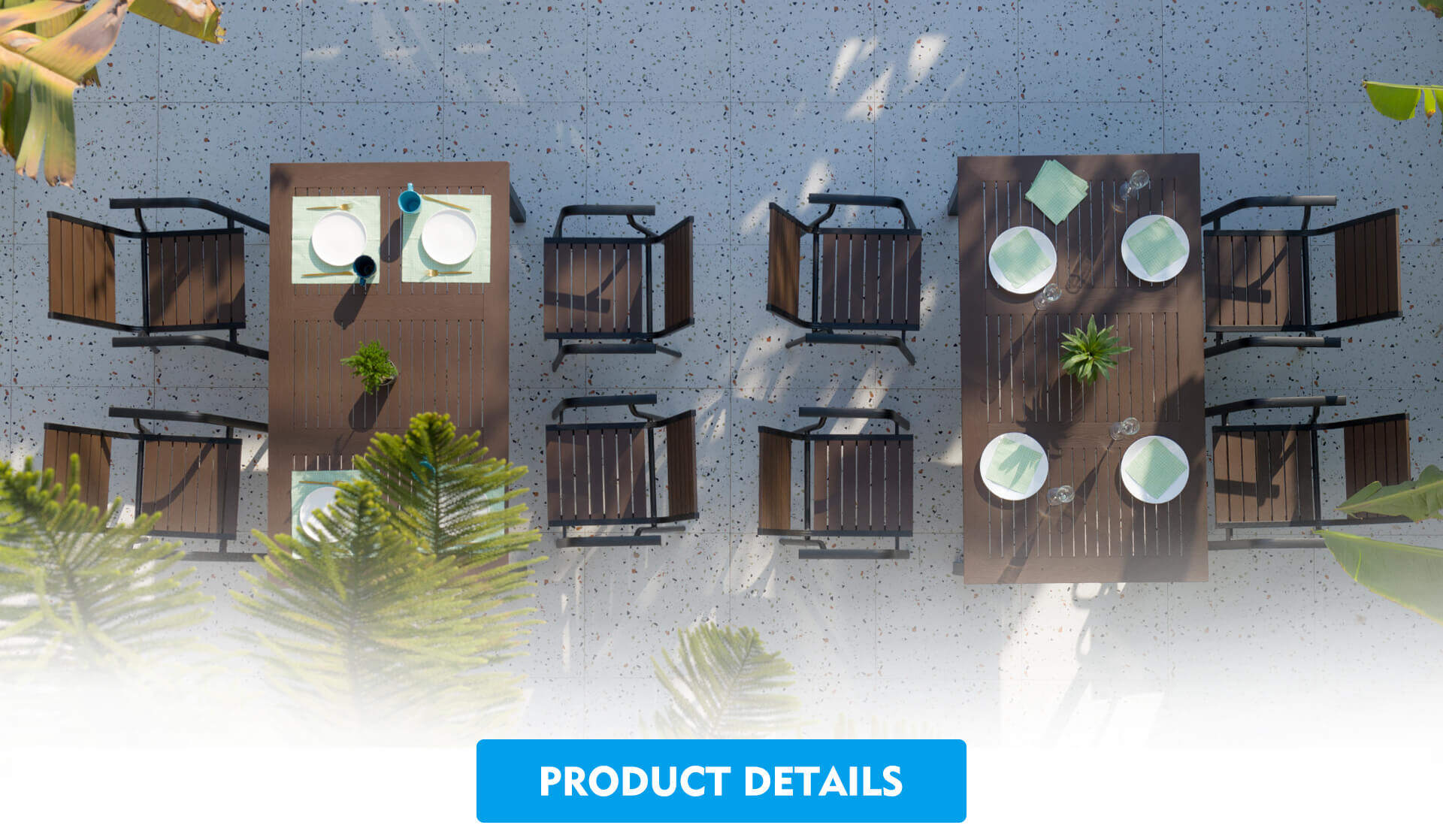

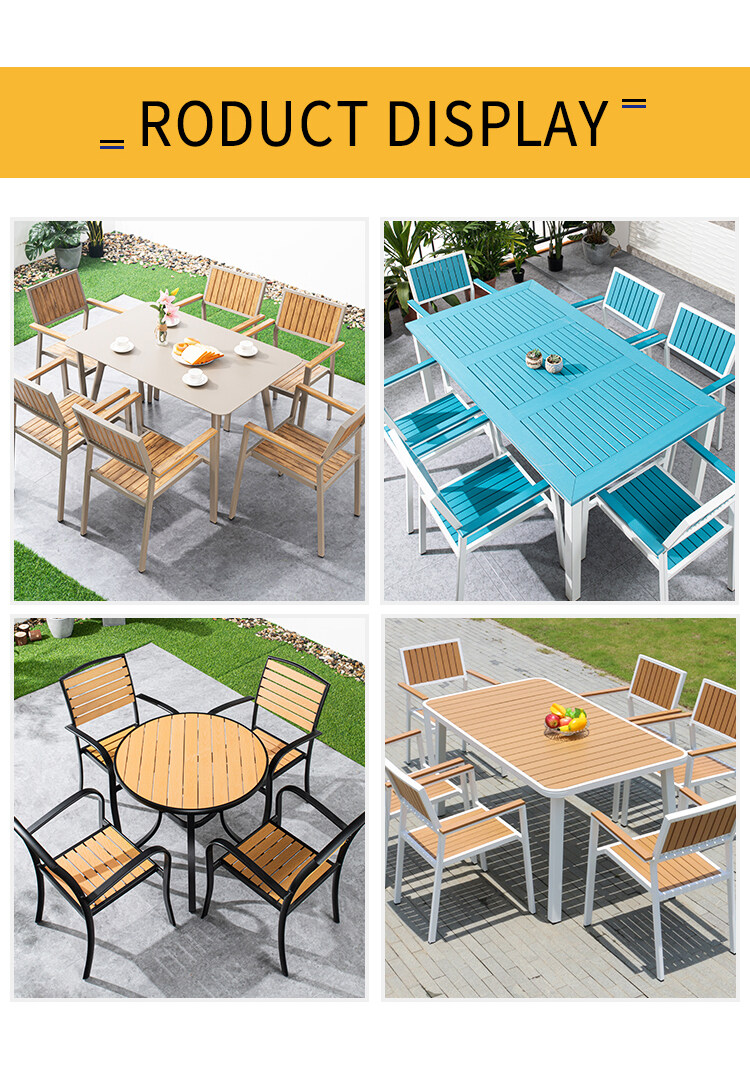

Wholesale Furniture Color Stackable White Modern Restaurant Set Dining Outdoor Patio Chairs

Product Details

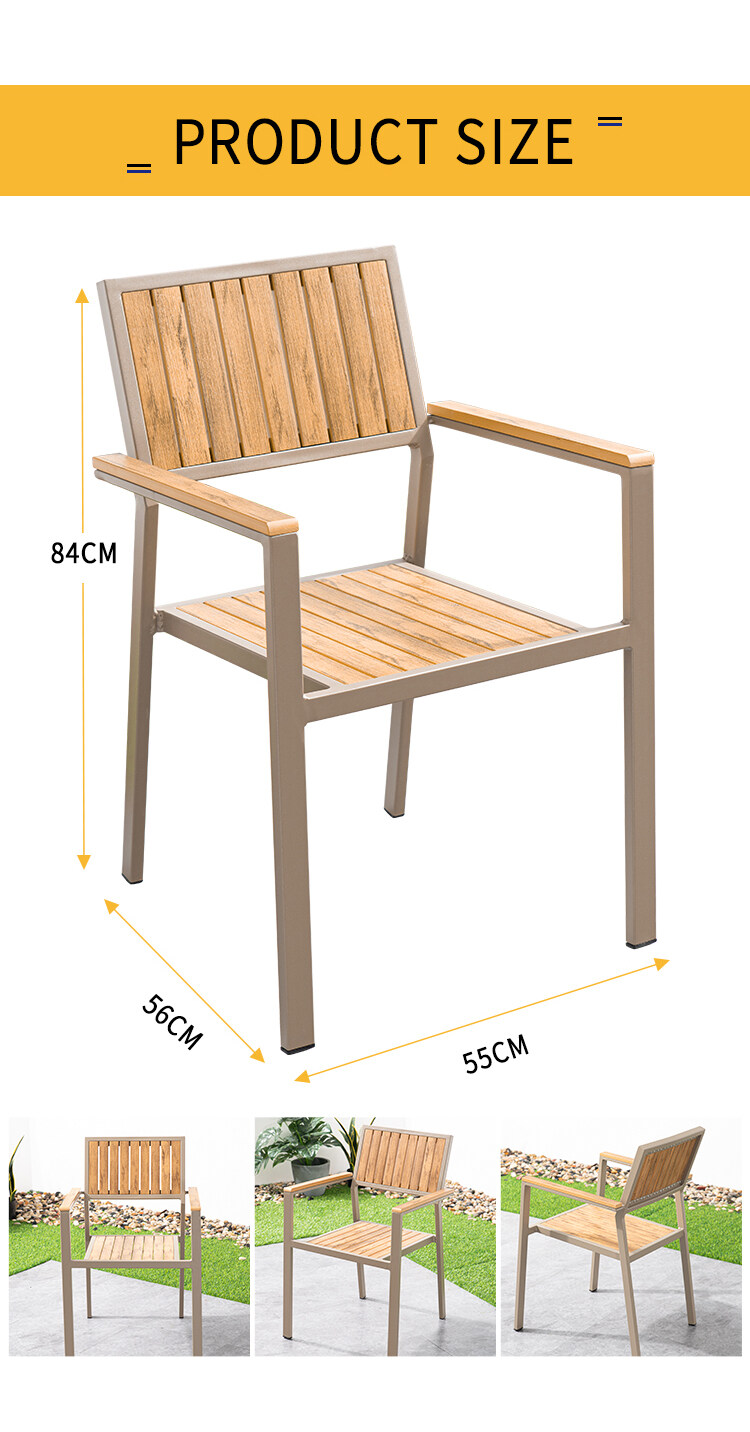

Overall size: W55*D56*H84CM

Material: aluminum frame+plastic wood

Alu. finish powder coated

Welded structure

Packing: in stack by paper sheet and wheel pallet

Loading qty: 840pcs/20GP 1800pcs/40HQ

Description

Since the beginning of the 21st century, the application of plastic-wood in the field of furniture manufacturing has attracted people's attention. Industry experts believe that the product performance of plastic-wood composite materials has been greatly improved, and the processing technology has been able to meet the needs of the furniture industry for materials. Specifically, in the field of furniture manufacturing, researchers have paid attention to the improvement of the strength and toughness, surface properties, durability and anti-change, antibacterial and antibacterial properties of plastic-wood composites, and weight reduction. With its stable characteristics and beautiful shape, it is loved by more and more people. The quantity and quality of plastic-wood furniture materials have made great progress compared with ten years ago. The research and development of plastic-wood composite materials has begun to pay attention to the furniture manufacturing industry. needs.

The manufacture of plastic wood furniture is different from solid wood furniture, and it cannot be manufactured in full accordance with the manufacturing ideas of plastic furniture. For a long time, the development of plastic wood furniture has been greatly restricted by technical conditions, and the progress of materials and market demand have forced the development of plastic wood furniture manufacturing technology. The development of plastic-wood furniture manufacturing technology is mainly reflected in three aspects: board manufacturing technology, profile/profile manufacturing technology, and progress in connection and assembly technology.

In the 1990s, when wood-plastic composite materials were not yet well-known, people were inspired by other wood-based panel manufacturing methods and began to use die-casting to manufacture furniture prefabricated parts, and assembled the prefabricated parts into simple panel furniture. Some people also use the method of hot pressing to manufacture the table top of the plastic wood board. In order to improve the strength of the board, a mesh layer woven from glass fibers is arranged in the middle of the board. With the emergence of plastic-wood extrusion technology, people began to combine single-screw extruders, twin-screw extruders and sheet molds at the beginning of this century to manufacture plastic-wood furniture sheets. WPC surface decoration technologies such as WPC imitation marble board manufacturing technology, paintable WPC furniture board manufacturing technology, and color WPC manufacturing technology have all developed rapidly. The wood-plastic board does not release volatile organic gases because it does not use adhesives, which is the outstanding advantage of the wood-plastic composite material.

At present, the research and development of plastic wood profile manufacturing technology mainly focuses on formula improvement, material rheology, mold size, process parameters, cavity design and so on. Plastic-wood profiles are mainly used to manufacture furniture backrests, legs, headboards and mirror frames, etc., and are especially suitable for manufacturing furniture products with various styles. Plastic wood furniture profiles can be manufactured by molding or injection molding. During compression molding, the wood-plastic composite material is first put into the mold cavity, the mold is closed, and the properties of the material are changed under the action of heat or pressure, and a shape that matches the shape of the mold is formed in the mold. Using this molding method, an organic curved surface can be produced, and the pattern texture of the surface can be processed at one time.

Feature

1.The chair frame is made of high grade aluminum alloy tube. Aluminum alloy material is light weight but sturdy as well as rustproof. It has better performance for outdoor use than iron material and lower cost than stainless steel material. In this case, it’s widely applied for making outdoor furniture.

2.Aluminum finish is outdoor powder coated which is available for various color and style. Meanwhile, it has a heavy adhesive force which is durable use for outdoor.

3. The seat and back is made of environmental friendly plastic wood slat. Plastic wood material is waterproof, UV resistant, anti crack, moisture and mildew proof. It meets people’s taste for solid wood but avoid disadvantage of solid wood. There’re different plastic wood colors for option, such as teak look, black, grey and brown etc.

4. Exquisite welded workmanship guarantees the sturdiness of chair and improves the aesthetic of the chair as well. It’s our stylish models with stackable design.

5.The chair can be used for restaurant, cafe, bar, bistro and hotel terrace as well as garden. It makes us enjoying outdoor life better.

FAQ

Q1:who are we?

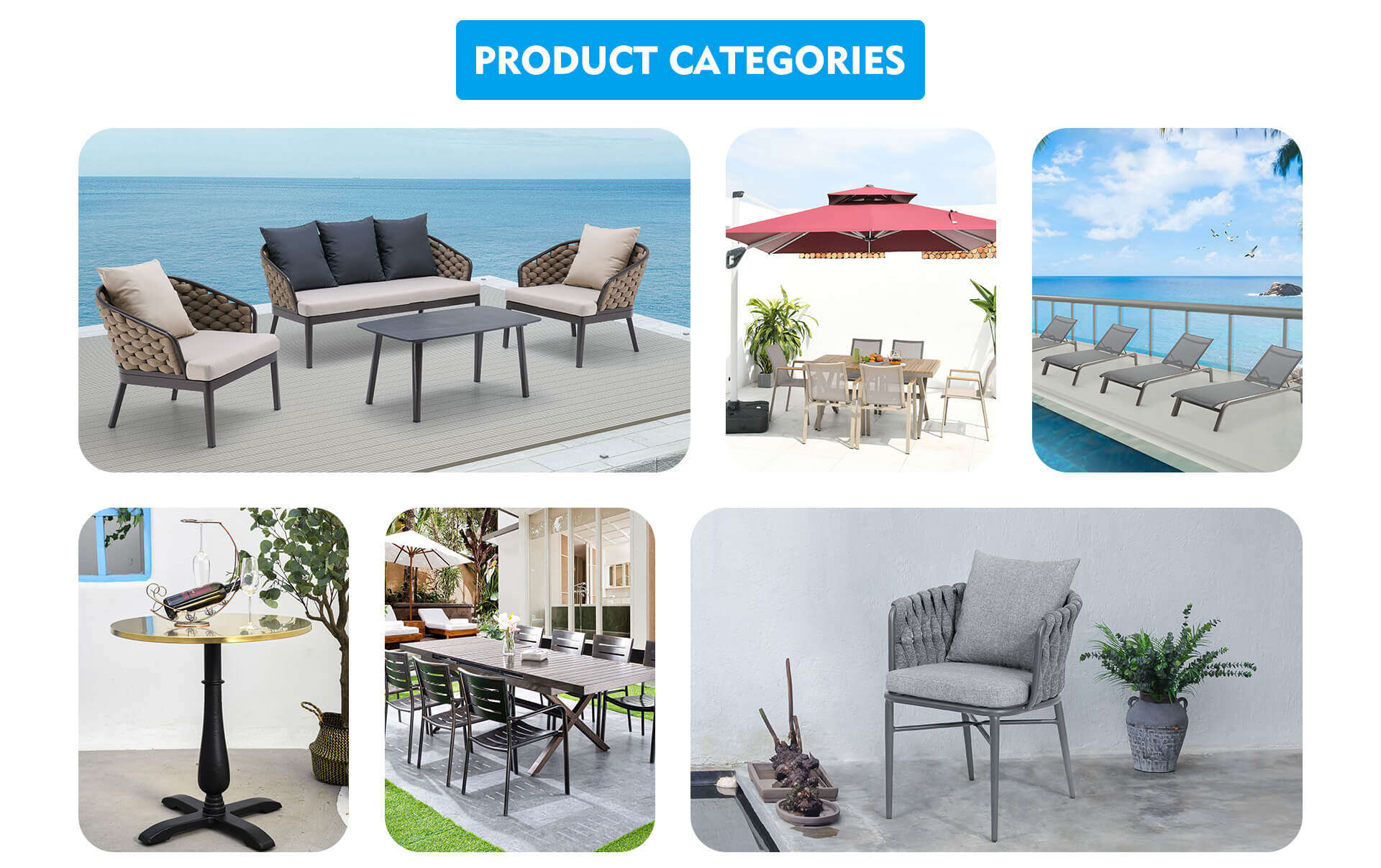

A:We are Foshan Vangarden Furniture Co.,Ltd and we professionally supply outdoor furniture including synthetic rope, aluminum alloy, plastic wood, outdoor fabric and PE rattan items.

It’s widely used for hotel /restaurant /bar /café / bistro terrace as well as garden /balcony /courtyard etc.

Q2:How can we guarantee quality?

A:Always a pre-production sample before mass production;

Always final Inspection before shipment.

Q3:why should you buy from us not from other suppliers?

A:We're manufacturing and trading company specializing in outdoor furniture industry more than 10 years. We can meet client's demand in the most and guarantee quality and delivery time. One stop service help saving money and time for clients.

Q4:What's the guarantee we can offer?

A:Basically we offer 1-2years guarantee. 3years or 5years guarantee can be offered according to different requirements.

Q5:What is our MOQ?

A:one for sample order 1X40HQ (4 designs mix loading is acceptable.)

Q6:What is our production and delivery time?

A:Normally 30-45days after order confirmed and down payment been paid. For flexible quantity project order, delivery time will be offered according to detail quantities and designs. For stock available products can be immediate shipment.

Q7:What's price terms we can offer?

A:Ex-work price, FOB price or CIF price.

Q8:What is our payment terms when order confirmed?

A:1.T/T: 30% deposit in advance and 70% balance

100% full payment for small order

L/C: Sight letter of credit.

Q9:Where's the outdoor furniture application?

A:Garden, Yard, Patio, Beach side, Poolside, Resort, Restaurant, Hotel, Coffee shop, Bar, and all outdoor leisure area.

Q10:What type of the product finish method ?

A:Outdoor powder coating / Electrophoresis/Anodize.

Q11:What's about our after-sale service & solution for quality faulty?

A:Provide outdoor furniture professional technical acknowledge for your training when needed. Provide high-resolution pictures for you to better sell products in your market. Careful and responsible after-sales service, guaranteeing a response to the problem within 3 days. Keep offering the latest popular designs and colors to help you to promote your market. Fully refund or replacement for quality faulty.